- May 20, 2019

- Posted by: info

- Categories: Advanced Materials, Research

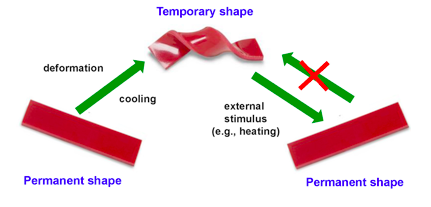

Shape memory polymers (SMPs) are smart materials representing a new and challenging field of research thanks to their unique shape memory property. The mechanism responsible for shape memory results from the combination of polymer structure and morphology, together with the applied processing and heat treatment (see Figure 1).

SMPs possess the advantages of large elastic deformations, low energy consumption for shape programming, low cost and density, potential biocompatibility, biodegradability, and excellent manufacturability. Thanks to such characteristics, SMPs have a promising future for applications as, e.g., MEMS devices, actuators, temperature sensors, packaging, fibers and films with insulating properties, digital storage, biomedical devices, and damping elements.

A recent collaboration with the Basic Chemicals and Plastics Research Center, Versalis S.p.A. has allowed the development of a new one-dimensional phenomenological model for SMPs, based on the so-called phase transition approach [P1]. The model is able to describe qualitative aspects of material behavior, involving both orientation and thermal retraction, as well as to predict experimental orientation processes for semi-crystalline polyethylene-based polymers with different densities.

Documents

Group publications

- [P1] G. Scalet, F. Auricchio, E. Bonetti, L. Castellani, D. Ferri, M. Pachera, F. Scavello. An experimental, theoretical and numerical investigation of shape memory polymers. International Journal of Plasticity, vol. 67, pp. 127–147 (2015).

Main collaborations

- Basic Chemicals and Plastics Research Center, Versalis S.p.A., Mantova