Computational Fluid Dynamics simulations of fluid flows inside microfluidic chip are used to characterize the mixing zones where polymeric Nanoparticles are mainly formed. The results obtained from the simulations provide also useful information that can be used optimize the nanoparticles production process.

Our CompMech group members Marco Bellotti and Alessandro Caimi, within the DSF – Digital Smart Fluidics project, within the “Call Hub Ricerca e Innovazione” program, performed with the commercial Software Ansys Computational Fluid Dynamics simulations of the mixing process inside a microfluidic chip to study the creation of nanoparticles. This phenomenon is due to diffusion and advection of polymeric molecules from a solvent solution to a buffer solution with the resulting precipitation of the newly formed nanoparticles. As studied through the numerical simulation the effect of the changes in geometry, total flow rate and flow rate-ratio was evident in the nanoparticles formation process.

This work is performed in collaboration with the Drug Sciences Department members, Enrica Chiesa, Prof. Ida Genta and Prof. Bice Conti.

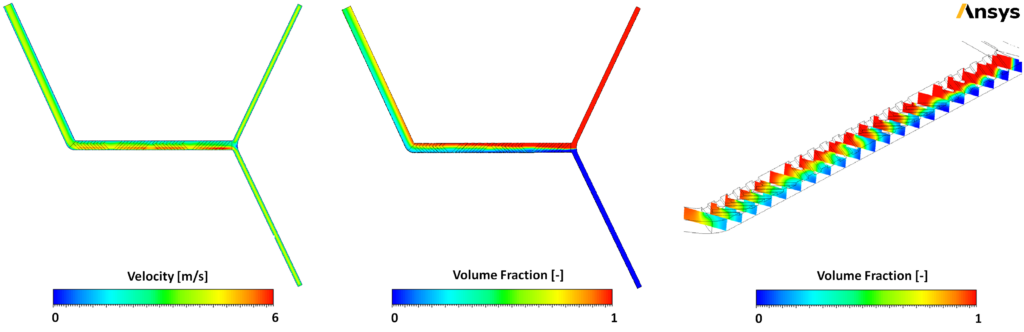

After the reconstruction of the fluid domain, the volume fraction of PLGA along the mid plane of the channel and on equally spaced cross-sectional planes were highlighted to identify the mixing profile of the solutions inside the channel. The velocity magnitude profile along the mid plane was also obtained to characterize the zones where the max velocities are obtained.

Fig. 1: Velocity magnitude and PLGA volume fraction profiles along the mid plane and the PLGA volume fraction on equally spaced cross-sectional planes gives qualitative information about the mixing process

July 5, 2022