Our CompMech Group member Chiara De Donno is working on an extensive experimental campaign for the mechanical characterization of mycelium-based materials (myco-materials).

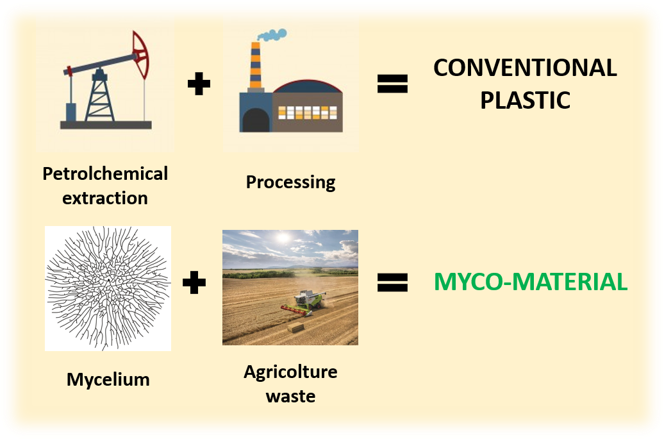

The use of fungal microorganism in biofabrication is opening great possibilities for converting agro-industrial waste into renewable and compostable myco-materials, which represent alternatives to petroleum-based foams, plastics, and others. The biofabrication method is low-energy and the derived products are both cost-competitive and performance-competitive, when compared to existing solutions currently available in the market. Myco-materials are an innovative solution that could contribute to mitigate the dangerous release of plastic micro-particles and of the related toxic chemicals into the environment, while limiting greenhouse gas emissions.

The experimental results show that the production procedure and post-treatments affect the mechanical properties. The results found are fundamental for providing guidelines on how to proceed in the design of targeted industrial products. The potential field of interest are multiple including automotive, packaging, thermal and acoustic insulation, medical, wearable, building/construction, and aerospace applications.

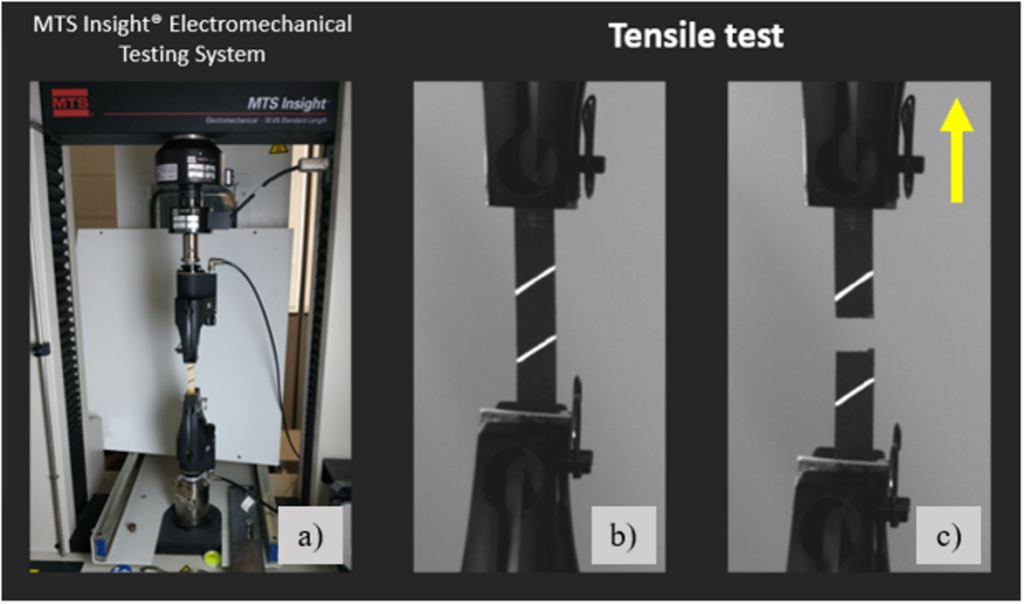

Fig. 2: Tensile tests for mechanical characterization: (a) experimental setup, (b) sample before the test, (c) sample after the test.

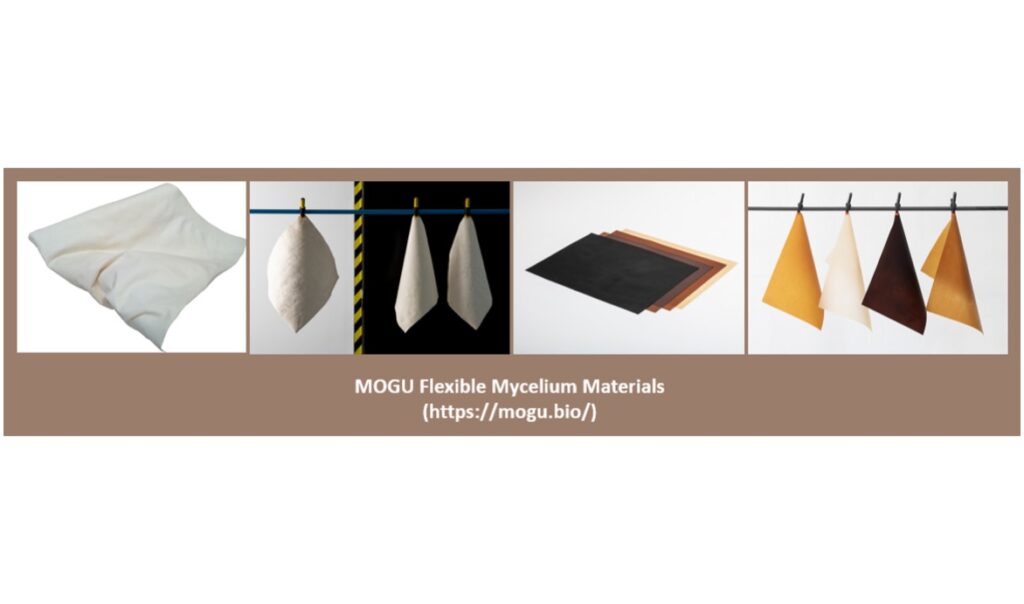

Fig. 3: Different types of available myco-materials – MOGU Flexible Mycelium Materials.

All the activities are running with the project Myco-Advanced leaTher matERials (MATER), funded by Cariplo Foundation, coordinated by Università degli Studi di Pavia (P.I. Prof. Daniele Dondi), with the support of MOGU S.r.l. and Politecnico di Milano.

February 10th, 2021