1. Sample Collections

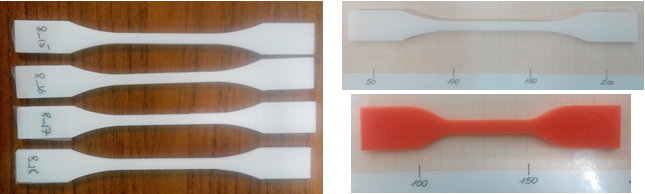

Dog-bone shape samples were printed with a 3D printer (LeapFrog Creatr) starting from a CAD model designed according the standard dimensions suggested by the ASTM D638. Samples were printed using different materials of different colours (e.g., ABS-red, ABS-green, ABS-white, and PLA-blue).

Figure 1. (a) Collection of four dog-bone shape samples of ABS white (n°8) material. (b). Representative sample of ABS white material (sample n°8.22). (c) Representative sample of elastomer (sample n°19.3)

2. Mechanical testing

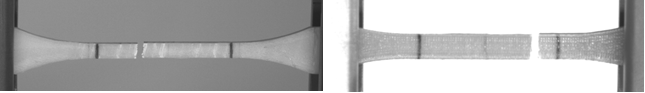

Uniaxial tensile test was performed using the MTS Insight Testing Systems, equipped by with a 10kN load-cell and with two wedge grips. The sample extension was measured using the ME-46 Video Extensometer. Uniaxial test was performed at the cross-head speed of 1 mm/min (and 5mm/min) until sample rupture.

Figure 2. Representative sample of: (a) ABS white material, b) elastomer material during extension.

Figure 3. Rupture of a representative sample of: (a) ABS white (sample n° 8.22), b) ABS red material (sample n°3.17).

3. Post-processing

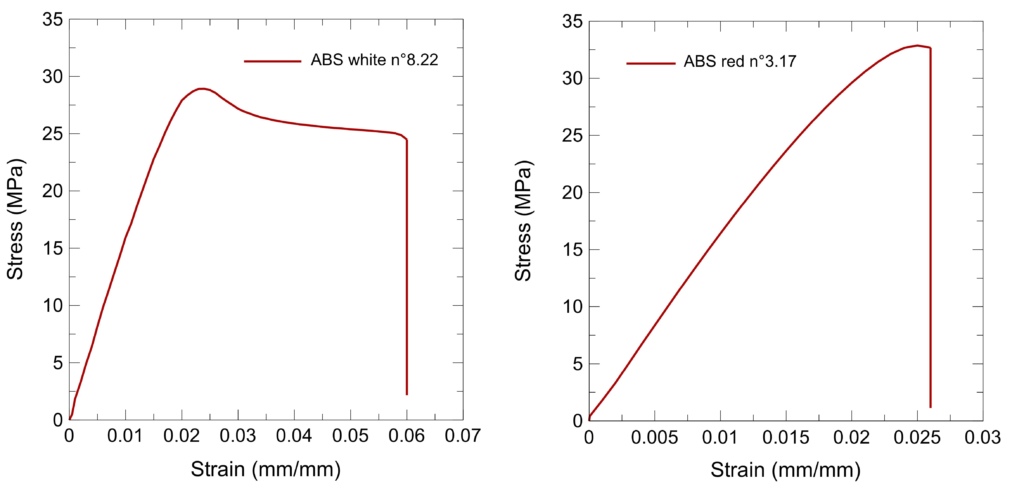

Figure 4. Representative stress/strain curves of: (a) ABS white (sample n°8.22); (b) (a) ABS red (sample n°3.17).