Impact of localized thermal treatment on PETG flexural behavior

A study was conducted to analyze the causes behind the brittle fracture of medical and industrial parts made of PolyEthylene Terephthalate Glycol (PETG).

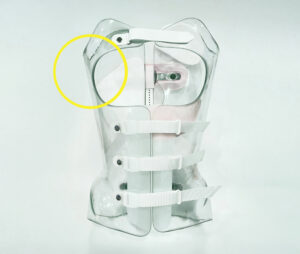

Figure 1: Frontal fracture of the brace.

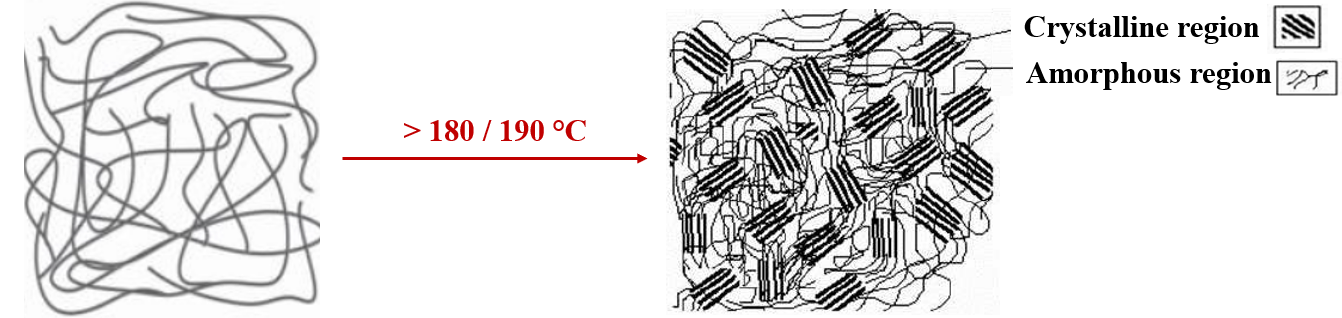

This type of failure can occur, for example, in orthotic braces (figure 1). A possible cause is that during the manufacturing process, the braces undergo thermoforming, in which the PETG is first heated in an oven at 140 °C for 5 minutes and then locally reheated to better define shape details. This process can alter the mechanical properties of PETG, as exposure to temperatures above 180°C induces changes in the polymer’s macromolecular structure. As a result, variations in stiffness, strength, and ductility are observed, leading to embrittlement and the appearance of defects (figure 2).

Figure 2: Crystallization process due to PETG heating.

Goal: assess the influence of PETG heating and its impact on the material’s ductile and brittle behavior.

Method: to evaluate the mechanical response as a function of the temperature to which the material was exposed, three-point bending tests were carried out at a speed of 13 mm/min following the ASTM D790-03 standard for flexural testing of plastics. The analysis was performed by A. Giovanelli under the supervision of B. Rossetti using the Litem BYC 200 machine, available at the Department of Civil Engineering and Architecture (DICAR) at the University of Pavia. The research activity was coordinated by S. Marconi, G. Alaimo, and F. Auricchio.

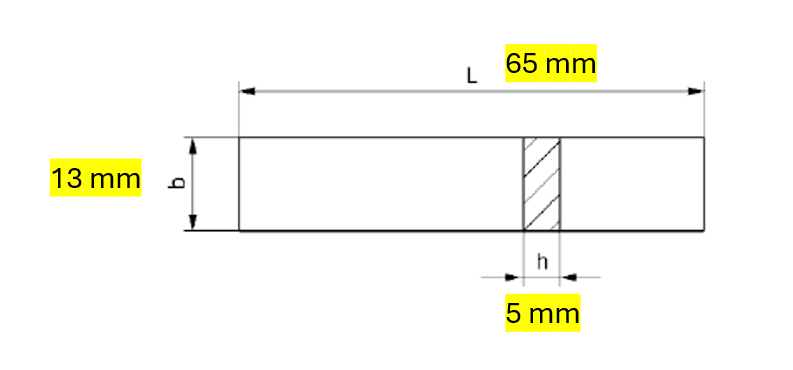

The rectangular specimens were cut from PETG plates, with dimensions shown in figure 3.

Figure 3: Dimensions of tested samples.

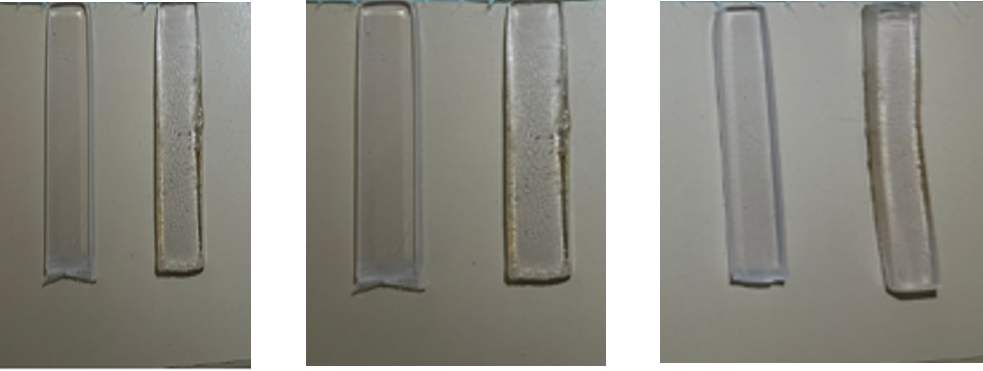

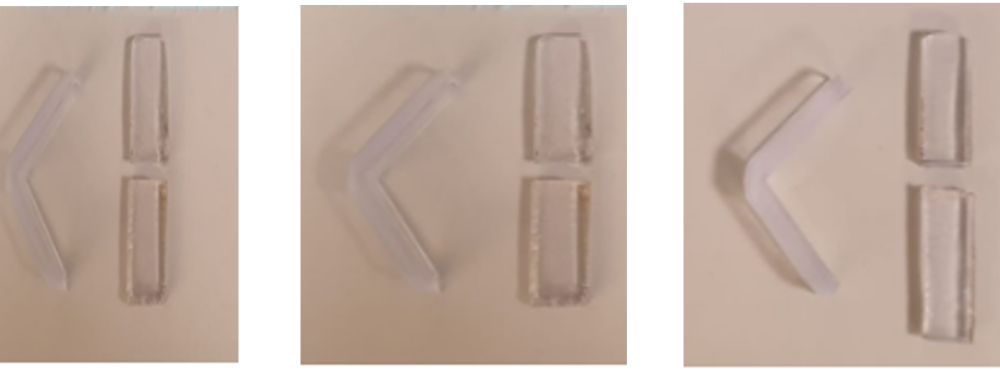

Specifically, three untreated and three overheat-treated samples at 400 °C for 10 seconds were tested (figure 4).

Figure 4: Pairs of untreated (left) and heat-treated (right) samples.

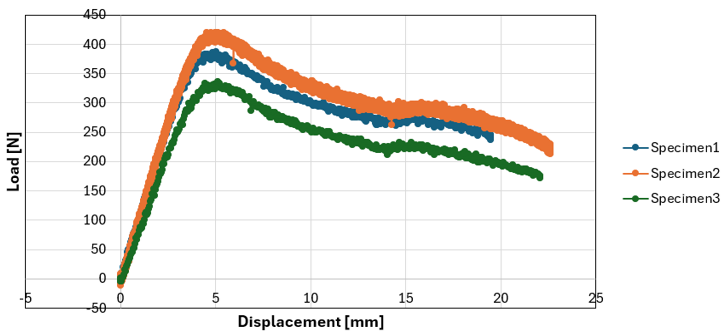

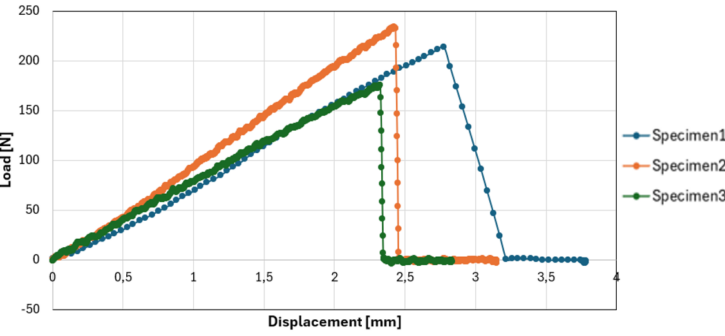

Results: figure 5 shows the specimens at the end of the test. As illustrated in figures 6 and 7, heating the material significantly changed its mechanical behavior: untreated samples exhibited ductile behavior with large displacement at the end of test, whereas the heat-treated ones showed brittle failure and absence of plastic deformation. Quantitatively, untreated samples reached higher average peak loads and elastic moduli compared to heat-treated samples (381 N vs 218 N, and 3464 MPa vs 2756 MPa, respectively).

Figure 5: Samples after testing – untreated on the left, heat-treated on the right.

Figure 7: Force–displacement curves for heat-treated samples.

This study demonstrated that PETG used in the production of functional devices and components is highly sensitive to exposure to elevated temperatures, particularly during the final thermoforming steps. The analysis allowed us to trace evidence of brittle fractures due to a change in the material’s internal structure caused by thermal exposure.