Prof. Ernst Rank

Technical University of Munich – Munich (Germany)

October 19, 2021 – 4.30 pm (CEST)

Zoom Meeting

https://us02web.zoom.us/j/84328331780?pwd=UEptSTZxd0ZBMy9ScHRKaG85eHVCdz09

Meeting ID: 843 2833 1780

Passcode: 171858

YouTube Live channel

https://www.youtube.com/channel/UCbuPu16F7DAuqSEX63agXyA

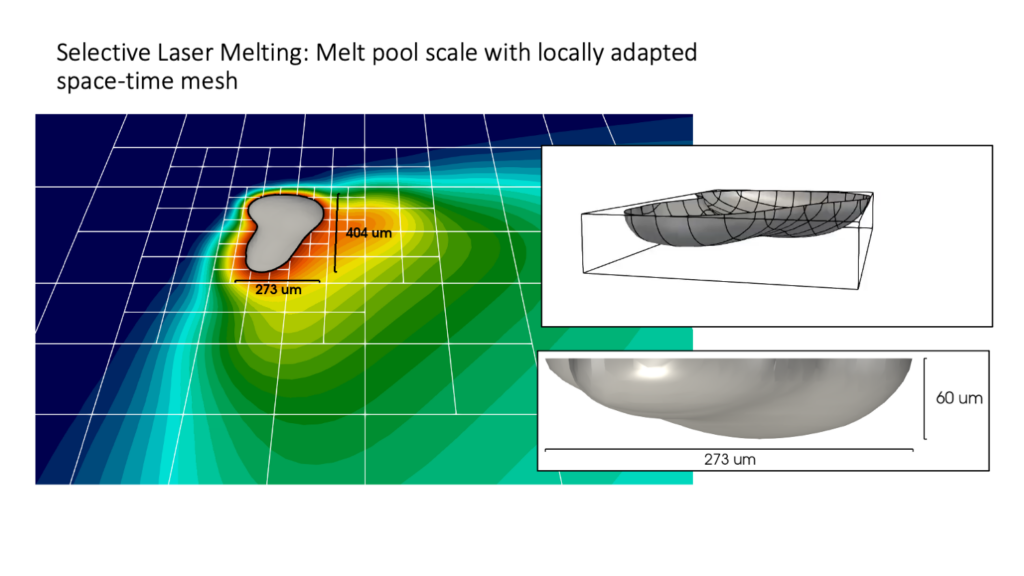

One of the largest challenges in simulation for Additive Manufacturing is the wide range of process and product specific relevant scales. This is not only true for the spatial scale, but in many cases even more for the temporal scales. Considering as an example Selective Laser Melting, and only focussing on a ‘macroscopic’ process simulation, the geometric scale of the laser spot and that of the typical length of a printing path differ by five to six orders of magnitude. The same scale range is relevant in time, when the local heating time and that of the full printing process of a part are considered. Even if only small, representative parts of SLM-processes are to be simulated, adaptive methods are mandatory.

While significant research has been conducted over the last few years on spatially adaptive AM simulation, only few results are available on the specific challenges of simultaneous spatial and temporal adaptation. In this talk, we will address a new approach applying space-time finite elements, with a fully 4-dimensional adaptation with respect to mesh and polynomial order of the shape functions. A data structure allowing the hp-adaptive n-dimensional simulation will be discussed.

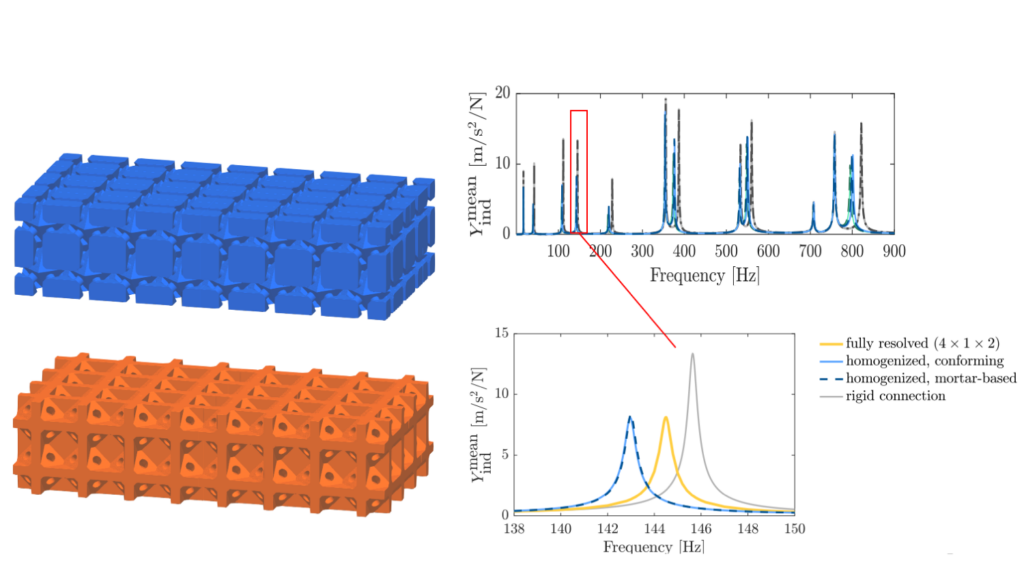

In the second part of the talk, we will address questions w.r.t. the large range of relevant scales for AM products. Geometric shapes and scales play an important role to control mechanical properties of built parts e.g. in case of lattice structures or for composite materials being designed to meet specific viscoelastic damping requirements. We apply a combination of the Finite Cell Method with an extension of the Mortar Method to develop a simulation system for optimizing viscoelastic properties of printed parts.

Biography: Ernst Rank is Professor emeritus from the Technical University of Munich. He studied Mathematics and Physics at the Ludwig-Maximilians-Universität of Munich and was awarded a doctorate from the School of Civil Engineering at the Technical University of Munich in 1985. Following a research year in the US and employment in an industrial environment at Siemens, he assumed in 1990 a professorship for Numerical Methods and Computational Sciences at the University of Dortmund, after which he was appoint-ed to TUM in 1997. Until 2019, he held the Chair for Computation in Engineering. Pro-fessor Rank was the Vice President for Research of TUM from 2002 to 2008. From 2006 to 2016, he was the Founding Director of the International Graduate School of Science and Engineering (IGSSE), and from 2015 to 2019, he held the position of Director of the TUM Institute for Advanced Study. Professor Rank conducts research on numerical mechanics and engineering informatics. His work focuses on high-order finite elements, immersed boundary methods, the inte-gration of numerical simulation with geometric modelling and on efficient simulation with applications e.g. in biomedical engineering or in additive manufacturing. A central objec-tive is to develop effective and intuitively usable simulation methods for the optimisation of industrial products and processes. Professor Rank is author or co-author of more than 400 papers in international journals, book chapters and peer reviewed conference proceedings. Among other awards he ob-tained the Konrad-Zuse Medaille (2009), the Federal Cross of Merit (2009), is Corre-sponding Member of the Nordrhein Westfälische Akademie der Wissenschaften und Künste (2014) and Member of the Bavarian Academy of Science (2017). Since 2018 he is Fellow of the International Association for Computational Mechanics (IACM).

Biography: Ernst Rank is Professor emeritus from the Technical University of Munich. He studied Mathematics and Physics at the Ludwig-Maximilians-Universität of Munich and was awarded a doctorate from the School of Civil Engineering at the Technical University of Munich in 1985. Following a research year in the US and employment in an industrial environment at Siemens, he assumed in 1990 a professorship for Numerical Methods and Computational Sciences at the University of Dortmund, after which he was appoint-ed to TUM in 1997. Until 2019, he held the Chair for Computation in Engineering. Pro-fessor Rank was the Vice President for Research of TUM from 2002 to 2008. From 2006 to 2016, he was the Founding Director of the International Graduate School of Science and Engineering (IGSSE), and from 2015 to 2019, he held the position of Director of the TUM Institute for Advanced Study. Professor Rank conducts research on numerical mechanics and engineering informatics. His work focuses on high-order finite elements, immersed boundary methods, the inte-gration of numerical simulation with geometric modelling and on efficient simulation with applications e.g. in biomedical engineering or in additive manufacturing. A central objec-tive is to develop effective and intuitively usable simulation methods for the optimisation of industrial products and processes. Professor Rank is author or co-author of more than 400 papers in international journals, book chapters and peer reviewed conference proceedings. Among other awards he ob-tained the Konrad-Zuse Medaille (2009), the Federal Cross of Merit (2009), is Corre-sponding Member of the Nordrhein Westfälische Akademie der Wissenschaften und Künste (2014) and Member of the Bavarian Academy of Science (2017). Since 2018 he is Fellow of the International Association for Computational Mechanics (IACM).