3D printing has found a great development in biomedical and tissue engineering field for scaffolds production made with biocompatible thermoplastic polymers or high viscosity materials such as hydrogels. In these compounds, it is possible to encapsulate cellular components such as cells, growth factors and drugs. This process, called bioprinting, consists of two basic elements: 3D bio-printer (the extrusion-based system), bio-ink (bio-material in which encapsulate cells or biological components).

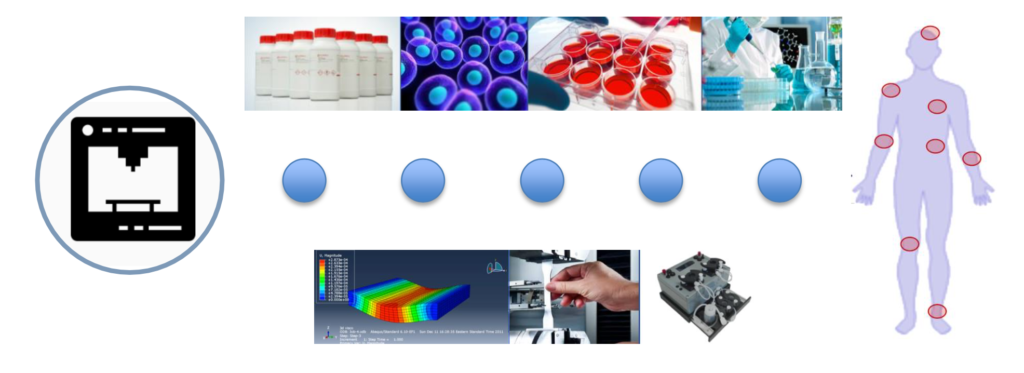

The typical bioprinting process starts from the isolation of the cells from the human body and then cells are expanded in-vitro until reaching a large number. The cells are encapsulated into the bio-material in order to create the bio-ink, then scaffolds are printed through a 3D bio-printer. After printing, scaffolds are crosslinked in order to maintain shape and stiffness; then they are incubated at 37 °C to allow cells to proliferate or differentiate inside the 3D structures. Colture medium is added during incubation time. 3D bioprinted scaffolds could be used as therapeutic devices themselves, as a testing platform for drug screening and discovery, or as an in vitro model system for disease [1].

CompMech bioprinting activities focuses on three different topics.

- Regenerative medicine

- 3D bioprinting mouse myoblast cell line (C2C12) to study cells differentiation into bio-ink and 3D modelling muscle fiber physiology (collab. Regenerative Medicine Laboratory, Dept. Sanità Pubblica Medicina Sperimentale e Forense, University of Pavia).

- Producing implantable bio-scaffolds rich in osteocytes and their calcified bone matrix, for orthopedic, maxillofacial, and otolaryngology surgery ((collab. IRCCS San Matteo Pavia).

- Disease 3D modelling

- 3D modelling in-vitro osteosarcoma cancer using an hydrogel-based bioink (collab. C. Ferrari – Lab. Chirurgia Sperimentale, University of Pavia and F. Riva – Dept. Sanità Pubblica Medicina Sperimentale e Forense, University of Pavia).

- Develop a 3D model of neuromuscular junction (NMJ) to study degenerative disease using iPSCs (collab. M. Pesce – IRCCS Fondazione Mondino, Pavia).

- Material characterization and simulation

- Computational modeling of crosslinked sodium alginate and gelatin hydrogel used for bioprinting applications (collab. M. Marino – Tor Vergata University of Rome)

- Mechanical characterization of GelMa 3D constructs (collab. IRCCS Centro Cardiologico Monzino, Milano)

References

[1] Mandrycky C, Wang Z, Kim K, Kim DH. Biotechnol Adv. 3D bioprinting for engineering complex tissues. 2016 Jul-Aug;34(4):422-434. doi: 10.1016/j.biotechadv.2015.12.011. Epub 2015 Dec 23

March 11th, 2020