Validation of numerical model for SS 316L steel handlebar (ASHEETA) through force-controlled bending test

This case study highlights the importance of both experimental and numerical test to validate and improve the performance of race bycicle components.

Using the Litem BYC 200 machine, a bending test up to a force value of 200N was performed on one side of the handlebar, with the supervisioning of the Protolab member B. Rossetti at the Department of Civil Engineering and Architecture of Università di Pavia (DICAR).

Figure 1: experimental set-up

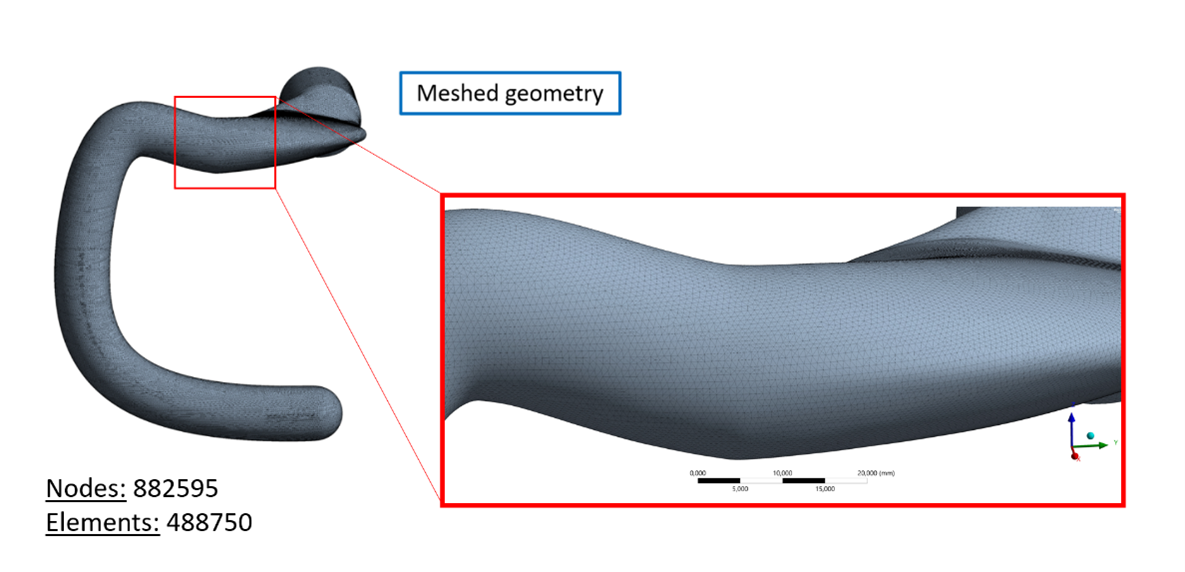

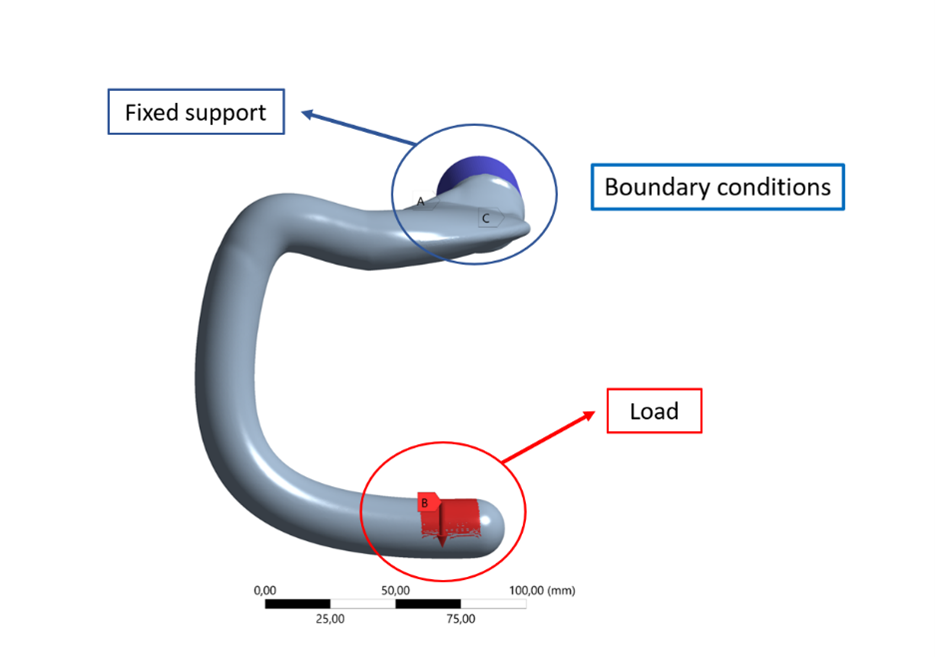

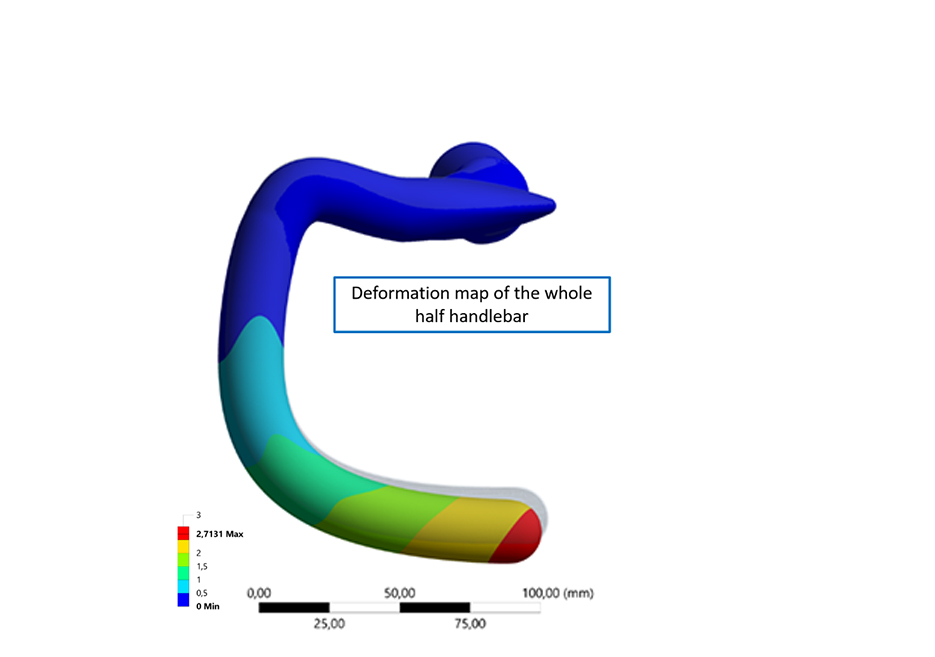

Experimental data were compared with the results of the numerical simulation carried out with the software Ansys on the corresponding half of the handlebar.

Figure 2: meshed geometry with details

Figure3: boundary conditions

Figure 4: deformation map of the whole handlebar

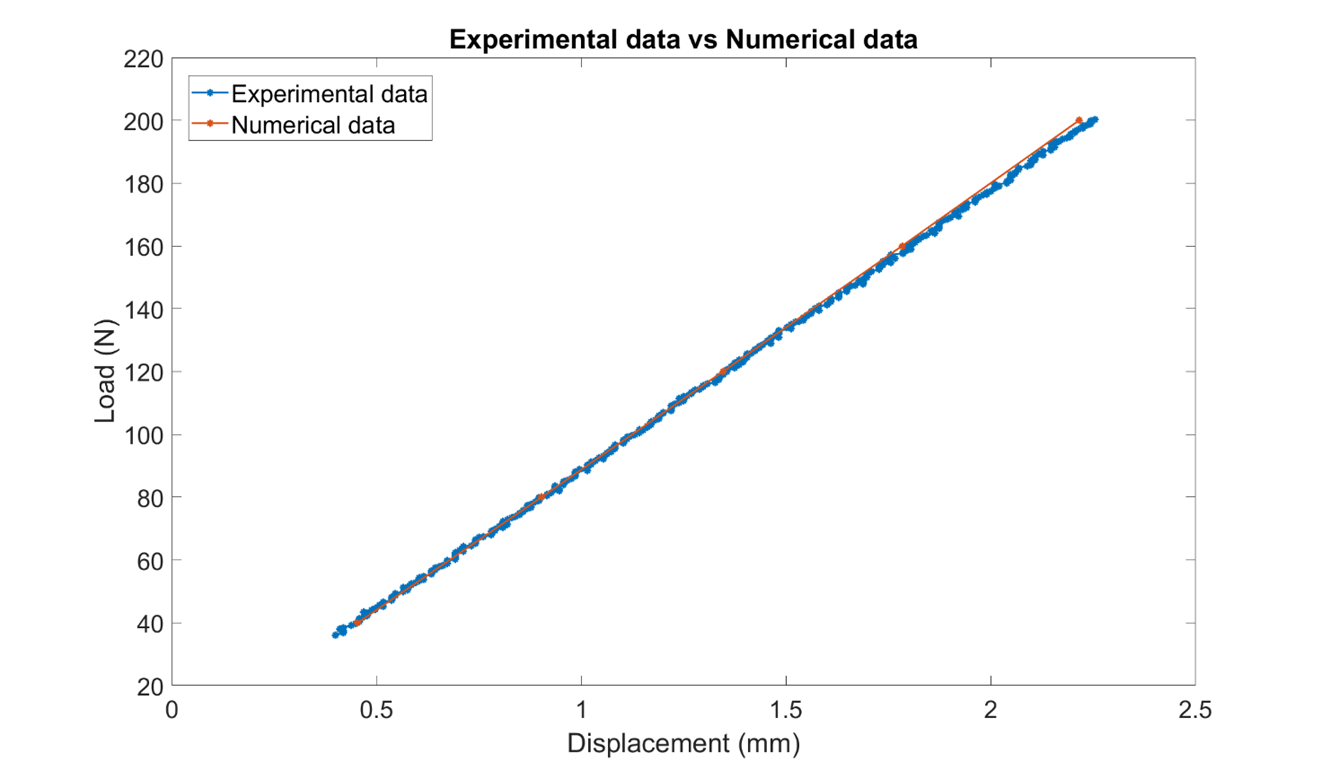

The visual analysis shows that the numerical model is highly accurate and well matches the experimental data, since they both reached a displacement value of approximatively 2.2 mm at the 200 N level.

Figure 5: comparison between experimental data and numerical data

Laboratory: