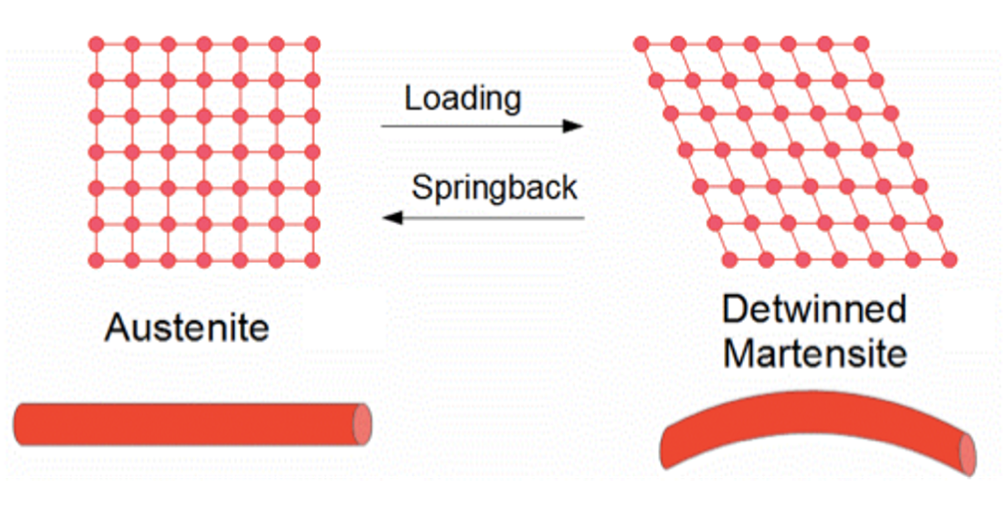

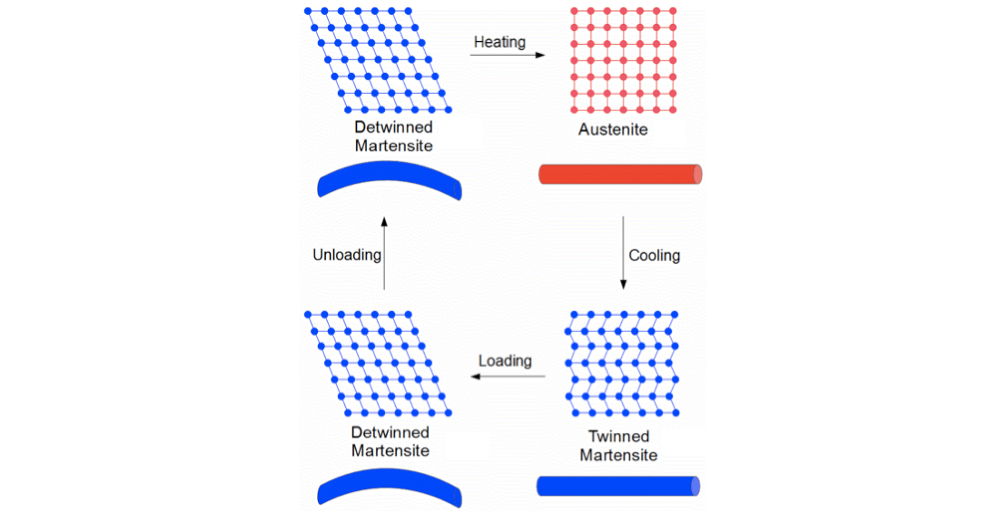

Shape memory alloys (SMAs) are smart materials showing two unique properties: superelasticity and shape-memory effect. Superelasticity allows SMAs to undergo large deformation upon loading at high temperatures (large strains can be undergone, until 8-10%) and to recover their original shape when unloaded (Figure 1). Shape memory effect is the ability to maintain a deformed shape up to heat induced recovery of the original shape (Figure 2).

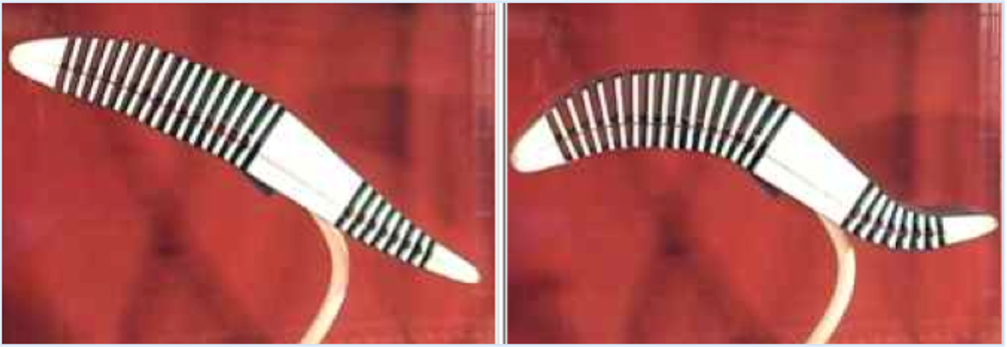

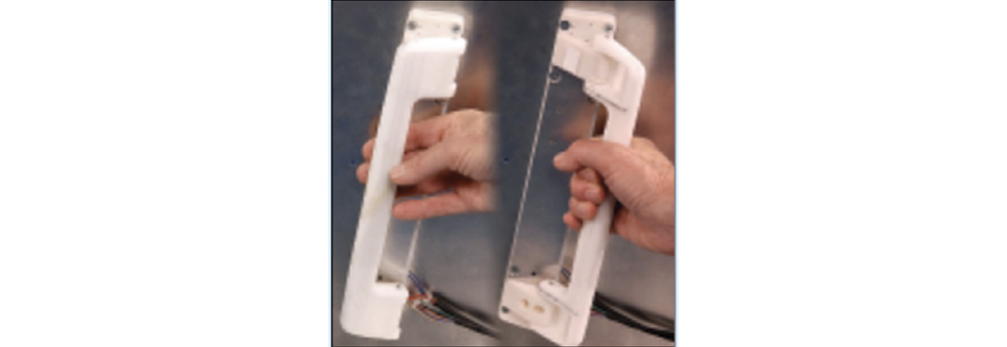

The advantages brought by SMA behavior make shape memory materials suitable for a variety of innovative applications (Figures 3, 4, 5, 6, 7), in fields like biomedical engineering (e.g. stents, surgery tools), aerospace (e.g. fastening devices), robotics (e.g. actuators), mechanical (e.g. SMA actuated valves) and civil engineering (e.g. damping devices).

Main collaborations:

- Saes Getters, Dr. Marco Urbano

- CNRS Ecole Polytechnique Palaiseau France, Prof. A. Costantinescu

- Chemistry Dept./Section Physical Chemistry, University of Pavia, Prof. U. Anselmi Tamburini, Prof. G. Spinolo

References

[P1] F. Auricchio, E. Boatti, M. Conti. SMA Biomedical Applications in “Shape Memory Alloy engineering: for Aerospace, Structural and Biomedical Applications”, editors: L. Lecce, A. Concilio, F. Auricchio. Elsevier, 307-341.

[P2] F. Auricchio, E. Boatti, M. Conti. SMA Cardiovascular Applications and Computer-Based Design in “Shape Memory Alloy engineering: for Aerospace, Structural and Biomedical Applications”, editors: L. Lecce, A. Concilio, F. Auricchio. Elsevier, 343-367.