In recent years, our laboratories have gained extensive experience in the processing of various materials and in adapting printing systems to the processing of experimental, unconventional and innovative materials, in the mechanical characterization of 3D printed materials and in the application of 3D printing technology to different sectors, especially in the biomedical field.

Our laboratories are equipped with the following equipment and instrumentation:

Additive technologies

- FDM (Fused Deposition Modeling) 3D printers: 3NTR A4v2, 3NTR A4v3, Leapfrog Creatr Dual Extruder, and Leapfrog Creatr HS

- Binder jetting 3D printer: 3DSystems Projet 460 Plus

- Polyjet 3D printer: Objet 260 Connex 3 Stratasys

- Stereolithography 3D printer: FORM 2 Desktop SLA

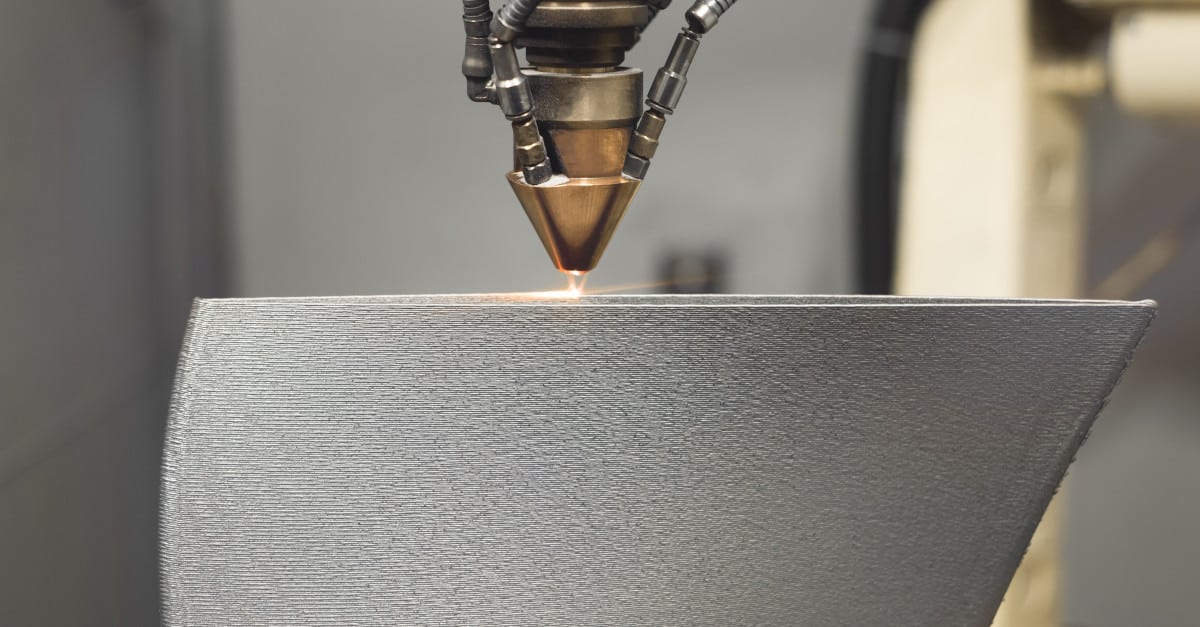

- SLM (Selective Laser Melting) metal 3D printer: Renishaw AM400

- Concrete 3D printer

- HP MJF 580

- Stratasys J750 Digital Anatomy

- Apium P220

- Markforged X7 Industrial

Mechanical testing systems and equipment

- MTS Insight System 10 kN – MTS System Corporation

- Video Extensometer NG – Messphysic Material Testing

- MTS MiniBionix 858 – MTS System Corporation

Work station and cluster

- Cluster HPC

- Workstation GPU Parallel Computing

Subtractive Manufacturing and Post-Production Technologies

- Chamber furnace: Nabertherm LH120/12

- 5 Axis CNC Machining Center

- Sandblast cabinet: Guyson EUROBLAST 4-AM

- Sawing machine: Special 411 M

- Rollwasch VibroBLAST