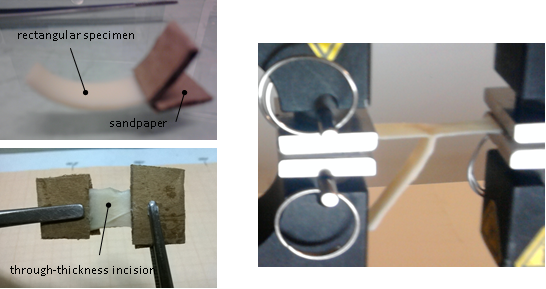

1. Specimen preparation

Rectangular strips of pig aorta was prepared: initial dissection plane was created through-thickness incision; sandpaper was placed at both ends of specimen with a super-adhesive gel in order to ensure clamping in the tensile-test machine and prevent slipping during test. The width, thickness, and length of each specimen were measured.

Figure 1. (a)Representative rectangular specimen of pig aorta. (b)Specimen mounted on the device.

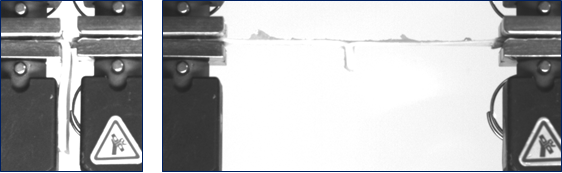

2. Mechanical testing

Mechanical testing was performed using the MTS Insight Testing Systems. The specimen were mounted on the testing machine, see Fig.2(a). A constant crosshead speed of 1 mm/min was used during the delamination process, see Fig.2(b). The applied load and resulting elongation were recorded continuously

Figure 2. Step of peeling test: (a) Step 1 – specimen mounted on the device before peeling test. (b) Step 2 – delamination of specimen during peeling test.

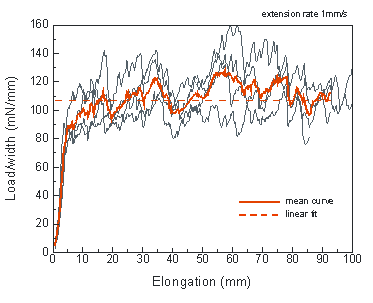

3. Post-processing

Figure 3. Load/width with respect to the dissection path (elongation) for all 7 rectangular specimens. The thick red curve represents the mean responses of the individual tissue tests.